John, I saw this on Julius Borges site, it almost looks like the planer is stationary and you slide the wood across it..

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| Shooting board--what’s the best? http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=10915 |

Page 1 of 1 |

| Author: | John Elshaw [ Tue Feb 13, 2007 5:38 am ] |

| Post subject: | |

I'm going back to old school methods and am going to plane my next couple back/side sets by hand. In the past I've just clamped one side and planed the other, then flipped it around and repeated. How do you all hold your boards down when planing very thin stock? I don't like the clamping idea because the clamp gets in the way of being able to make long even passes. I thought about a shooting board, but it would have to be very thin to hold a 2.5 mm back/side, then I would be afraid of it not holding the board. What do you guys all do? Thanks! John |

|

| Author: | LanceK [ Tue Feb 13, 2007 5:44 am ] |

| Post subject: | |

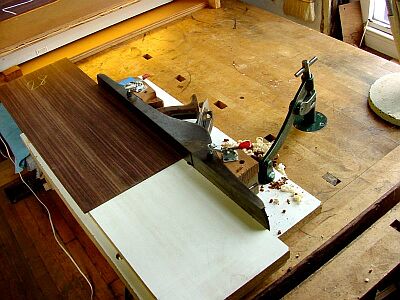

John, I saw this on Julius Borges site, it almost looks like the planer is stationary and you slide the wood across it..

|

|

| Author: | Mark Tripp [ Tue Feb 13, 2007 6:06 am ] |

| Post subject: | |

I use a cobbled version of what Lance shows here - plane is stationary and the wood runs across. In fact that is what I'm dong in my avatar photo... -Mark |

|

| Author: | JohnAbercrombie [ Tue Feb 13, 2007 6:09 am ] |

| Post subject: | |

Mark, Brock- I had a long post composed showing my version of your edge-shooting arrangements, when I realized that John seems to be asking about planing the surfaces of the top/back (ie thicknessing). I may have mis-read the original post. John |

|

| Author: | LanceK [ Tue Feb 13, 2007 6:11 am ] |

| Post subject: | |

Opps! You are correct John! I miss read that post...

|

|

| Author: | SteveCourtright [ Tue Feb 13, 2007 6:12 am ] |

| Post subject: | |

JohnA, I think you are correct. JohnE wants to thickness plane the faces. That is my read. |

|

| Author: | JohnAbercrombie [ Tue Feb 13, 2007 6:12 am ] |

| Post subject: | |

John- I've always moved clamps and cleats around when I had to do this, and found it clumsy. Perhaps this would be a good application of vacuum (perforated workboard?) to hold down the work? Coupled with a thin (2mm?) stop cleat it might do the trick. Not very traditional, though! John |

|

| Author: | John Elshaw [ Tue Feb 13, 2007 6:32 am ] |

| Post subject: | |

Yes, you guys are correct, I'm looking for a better way to hold down the boards while I plane the surface. Like John A. mentioned above, this is a very clumsy way to do this, and it prevents using nice long even strokes with the plane. I always end up having to clamp in a couple places because I usually need to plane at an angle, so the clamps restrict the plane even more. Surely somebody out there has a better way to do it than this. John |

|

| Author: | Mark Tripp [ Tue Feb 13, 2007 7:14 am ] |

| Post subject: | |

Doh! Sorry! -Mark |

|

| Author: | Rob Girdis [ Tue Feb 13, 2007 7:39 am ] |

| Post subject: | |

I tack the wood to be planed down to a piece of MDF. A small nail (3/4" in length) in each corner is all it takes. Pre-drill the holes with a 1/16" bit, then drill a countersink hole large enough to accomodate the head of the nail using the 1/16" as a center to below the surface that you will plane to. Tack the nails in and set them with a punch. Keep an eye on the nails as you plane and set them deeper if you need to. I use a cheap and funky chisel with a very rounded bevel to pry the nails up with when I'm done. If you keep the nails close to the end of the board they will come out easier. Come straight at the nails with the chisel when prying them out to avoid splitting the wood. Also, I found something called Ultralight MDF here in Seattle that gives up the nails easily. It is softer and lighter than the regular MDF but is just as flat and stable (if kept dry). |

|

| Author: | JBreault [ Tue Feb 13, 2007 7:42 am ] |

| Post subject: | |

Bench dogs and an end vise? That or tack the board down in the waste area. |

|

| Author: | nathan c [ Tue Feb 13, 2007 7:51 am ] |

| Post subject: | |

John, I thicknessed my back & top by clamping one end and planing the other. If I'm not mistaken it's pretty much what you have done. Here's a pic my back in the middle of roughing. I can't find the one after smoothing and scraping, but it looks much better than the roughed up one. |

|

| Author: | Colin S [ Tue Feb 13, 2007 9:28 am ] |

| Post subject: | |

John, I always plane my tops to thickness, and often my Back and sides as well, it's very satisfying. I rest the wood on 18mm MDF at the end of my island bench, then hold it down at the end with a wooden slat across it and three cam clamps. I can then work on 90% of the board with the plane. Reverse and clean up the end that was clamped. For sides I use a slat and clamps at both ends. The slat acts as a caul to apply even pressure from the clamps across the whole end of the board. You really don't need to clamp it down very hard as you should only be using minimal pressure to remove the excess. Colin |

|

| Author: | Martin Turner [ Tue Feb 13, 2007 10:16 am ] |

| Post subject: | |

I have a 2mm thick scrap of rosewood side that I clamp across my bench and use as a bench stop for the top/side/back I'm planing or scraping. |

|

| Author: | Arnt Rian [ Tue Feb 13, 2007 10:57 am ] |

| Post subject: | |

Like Colin, I hand plane my sound boards and some of my backs and sides. I use a single clamp on the plates and a bench stop on a flat board to keep the plates from rotating. The board is in turn clamped between a bench dog and the tail vise on my "hovelbenk" (Scandinavian type low planing bench). The single clamp does not get much in the way of the work, but I have to flip the plate a few times to check my progress. |

|

| Author: | CarltonM [ Tue Feb 13, 2007 1:32 pm ] |

| Post subject: | |

[QUOTE=Rob Girdis]A small nail (3/4" in length) in each corner is all it takes. Tack the nails in and set them with a punch. I use a cheap and funky chisel with a very rounded bevel to pry the nails up[/QUOTE] Rob, I've used small screws. One in each corner--easy in/easy out for checking plate thickness. Brass screws would be best, so if you accidently nick one it won't seriously damage your blade. Everything was going so smoothly when I did this on some junk spruce that I planed it too thin--really fast. |

|

| Author: | CarltonM [ Tue Feb 13, 2007 1:35 pm ] |

| Post subject: | |

[QUOTE=John Elshaw] I thought about a shooting board, but it would have to be very thin to hold a 2.5 mm back/side[/QUOTE] John, I believe you were meaning to say "bench hook." |

|

| Author: | jfrench [ Tue Feb 13, 2007 1:57 pm ] |

| Post subject: | |

Same setup as Colin for me. |

|

| Author: | Arnt Rian [ Tue Feb 13, 2007 10:04 pm ] |

| Post subject: | |

[QUOTE=CarltonM] [QUOTE=John Elshaw] I thought about a shooting board, but it would have to be very thin to hold a 2.5 mm back/side[/QUOTE] John, I believe you were meaning to say "bench hook." [/QUOTE] Yes, the reason the first few post in this tread are confusing is that the topic title is misleading. A shooting board is: “…a woodworking workbench accessory which is used in combination with a hand plane to trim and square up the edges and ends of boards.”

to quote from Wikipeda, and we typically use one to joint plate halves of course. “A bench hook is a workbench accessory used in woodworking. The purpose of the bench hook is to provide a stop against which a piece of wood being worked can be placed to hold it steady whilst cutting, planing, or chiselling”, again from Wikipeda. Wikipeda |

|

| Author: | Homeboy [ Fri Feb 16, 2007 5:39 am ] |

| Post subject: | |

Arnt, That is one hell of a bench! I want one of those. Did you make that bad boy? Blake |

|

| Author: | Andy Matthews [ Fri Feb 16, 2007 8:37 am ] |

| Post subject: | |

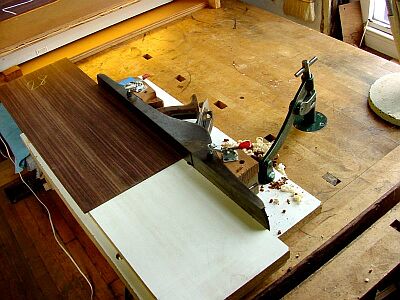

Just so happens I've made one today. Simple but effective. Shown with my veritas number 6

|

|

| Author: | KiwiCraig [ Fri Feb 16, 2007 8:51 am ] |

| Post subject: | |

On one end of my bench a have a 3 foot square piece of 1/2 " thick glass. I cover this with posterboard. I have this very level and true . It is a handy area for planing and as a level reference. I simply cam clamp a stop at one end , which is only 2m.m. thick ,but 3 " deep , so it has no "give" . It's about two feet long so as to not interfere with my plane stroke. This way ,I can plane the whole plate without any interference of hold downs etc . Works perfectly ! |

|

| Author: | KiwiCraig [ Fri Feb 16, 2007 9:17 am ] |

| Post subject: | |

My above post is not a shooting board of course.It's for planing plate thickness |

|

| Author: | MarkJ [ Sat Feb 17, 2007 9:49 pm ] |

| Post subject: | |

I use double sided wood workers tape (NOT carpet tape) to stick the top or back to my work board surface. The work surface is very flat and I also use it for a shooting board for joining the top/back. It only takes a few short (1 1/2 inch) pieces at the corners and the edges to hold the material down (get all the scraping dust off first. Use a thin knife blade to ease the tape up to unstick the piece. |

|

| Author: | Arnt Rian [ Sat Feb 17, 2007 10:47 pm ] |

| Post subject: | |

[QUOTE=Homeboy] Arnt, That is one hell of a bench! I want one of those. Did you make that bad boy? Blake[/QUOTE] I wish that was mine, but alas no such luck. It it a picture ripped from the Wikipeda article I put up a link to. My bench is much more modest (not to mention planes; those mitre planes go for outrageous prices!). |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|